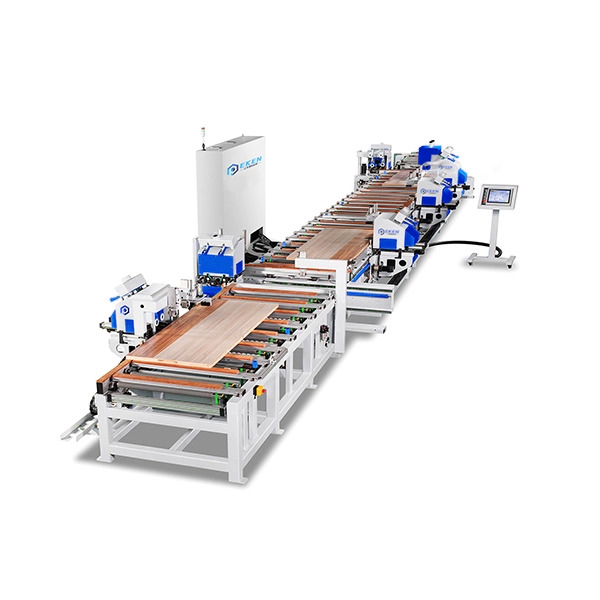

We at EKEN CNC are devoted to revolutionizing the furniture manufacturing process with our trusted technology and unmatched efficiency. One of our most popular products, the EKEN Double Sides Edge Banding Machine Line, can band all four edges of a panel simultaneously, making it much easier to edge band. In addition to increasing output, this also reduces the need for manual labor. Let’s explore how our technology can revolutionize your business in more detail.

Unmatched Efficiency in Edge Banding

The EKEN Double Sides Edge Banding Machine Line stands out as a game-changer in the manufacturing process. By enabling the complete edge banding of four sides of the panel simultaneously, we significantly reduce the time spent on this crucial task. The efficiency of our machines means less downtime and more output, making them an invaluable addition to any furniture production line. Moreover, our variety of edge banding machine connection solutions caters to diverse applications. Whether you are dealing with different materials or varying production scales, our machines adapt seamlessly to meet your specific needs. This flexibility is key to maximizing your operational efficiency and ensuring that you can meet market demands effectively.

Independent Research and Development

At EKEN, we take pride in our commitment to innovation through Independent Research and Development. Our furniture production line is not just a product; it represents our dedication to advancing technology in the industry. Every component, from hardware to software, is developed and produced in-house, ensuring quality and reliability. Our team of experts has designed an intelligent, automatic, efficient, and economical system that simplifies the manufacturing process. This dedication to R&D allows us to keep our products at the cutting edge, providing our clients with the tools they need to thrive in a competitive market.

Comprehensive Support and Service

We understand that investing in a new machinery system can be daunting. That’s why we offer comprehensive support, including on-site installation and commissioning by our experienced construction team. Our engineers not only install the machinery but also provide thorough training to ensure your staff is well-equipped to operate the system efficiently. Our full-service approach means we are with you every step of the way. From initial setup to ongoing support, we are committed to helping you maximize the potential of your furniture production line. Our goal is to empower your business with the tools and knowledge necessary for success.

Conclusion

In summary, EKEN CNC is your partner in revolutionizing the furniture production line. Our EKEN Double Sides Edge Banding Machine Line enhances efficiency by completing edge banding on all four sides of a panel at once, saving you time and labor. With our dedication to Independent Research and Development, we ensure that our machines are both innovative and reliable. Coupled with our comprehensive support services, we are ready to help your business achieve greater heights in the manufacturing process.

EKEN CNC: Transforming Furniture Production with Innovative Edge Banding Solutions

We at EKEN CNC are devoted to revolutionizing the furniture manufacturing process with our trusted technology and unmatched efficiency. One of our most popular products, the EKEN Double Sides Edge Banding Machine Line, can band all four edges of a panel simultaneously, making it much easier to edge band. In addition to increasing output, this also reduces the need for manual labor. Let’s explore how our technology can revolutionize your business in more detail.

Unmatched Efficiency in Edge Banding

The EKEN Double Sides Edge Banding Machine Line stands out as a game-changer in the manufacturing process. By enabling the complete edge banding of four sides of the panel simultaneously, we significantly reduce the time spent on this crucial task. The efficiency of our machines means less downtime and more output, making them an invaluable addition to any furniture production line. Moreover, our variety of edge banding machine connection solutions caters to diverse applications. Whether you are dealing with different materials or varying production scales, our machines adapt seamlessly to meet your specific needs. This flexibility is key to maximizing your operational efficiency and ensuring that you can meet market demands effectively.

Independent Research and Development

At EKEN, we take pride in our commitment to innovation through Independent Research and Development. Our furniture production line is not just a product; it represents our dedication to advancing technology in the industry. Every component, from hardware to software, is developed and produced in-house, ensuring quality and reliability. Our team of experts has designed an intelligent, automatic, efficient, and economical system that simplifies the manufacturing process. This dedication to R&D allows us to keep our products at the cutting edge, providing our clients with the tools they need to thrive in a competitive market.

Comprehensive Support and Service

We understand that investing in a new machinery system can be daunting. That’s why we offer comprehensive support, including on-site installation and commissioning by our experienced construction team. Our engineers not only install the machinery but also provide thorough training to ensure your staff is well-equipped to operate the system efficiently. Our full-service approach means we are with you every step of the way. From initial setup to ongoing support, we are committed to helping you maximize the potential of your furniture production line. Our goal is to empower your business with the tools and knowledge necessary for success.

Conclusion

In summary, EKEN CNC is your partner in revolutionizing the furniture production line. Our EKEN Double Sides Edge Banding Machine Line enhances efficiency by completing edge banding on all four sides of a panel at once, saving you time and labor. With our dedication to Independent Research and Development, we ensure that our machines are both innovative and reliable. Coupled with our comprehensive support services, we are ready to help your business achieve greater heights in the manufacturing process.

Wonderful! Share this Blog:

Categories

Ekenmac Secures Major European Order: Russian Customer Once Again Chooses Eken’s Composite Door Production Line

The Future of Door Manufacturing is Here: Automated & Smart

One Belt and One Road Woodworking Machinery Solutions

Eken Woodworking Machinery Ships Custom Solution to Jordan

Last-Minute Christmas Rush: Secure Your Woodworking Machinery Now!

Eken Woodworking Machinery: Speed and Trust in Action for Bangladesh Customer