At EKEN CNC, we take pride in our commitment to excellence in the furniture industry. Our focus is on providing trusted solutions that cater to the evolving needs of our customers. With our innovative EKEN Thailand Panel Furniture Production Line, we are set to transform the way furniture is manufactured, making it more efficient and tailored to individual preferences.

Meeting Diverse Customization Needs

In today’s fast-paced market, it’s essential to follow up on customer needs and factory area customization to meet diversified customization requirements. We understand that every client has unique specifications, and our furniture production line is designed to accommodate these variations. By utilizing advanced technology, we ensure that our production lines can adapt to different styles and designs, allowing for a seamless integration of customization in every project. Our approach is not just about meeting the current demands but also anticipating future trends. This proactive strategy helps us stay ahead in the competitive landscape, ensuring that our clients receive the most innovative solutions available in the market.

Advanced Machinery for Enhanced Efficiency

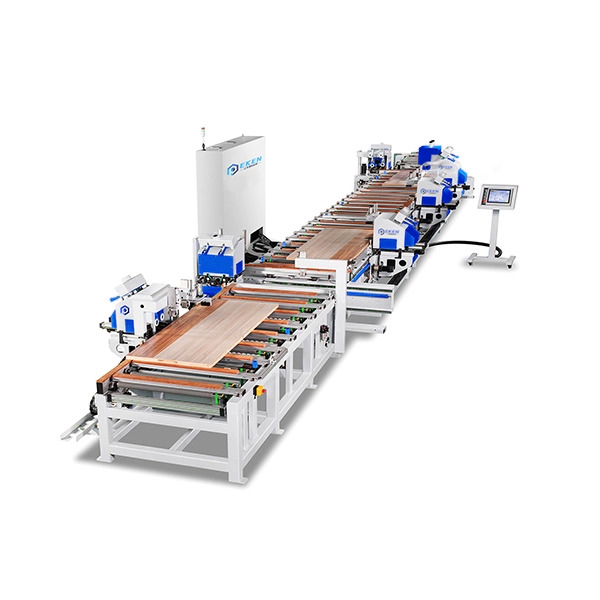

Our EKEN Thailand Panel Furniture Production Line features reliable machinery that enhances production efficiency. One of the standout components is the double-end edge banding machine production line. This technology allows for precise edge finishing, ensuring that every piece of furniture meets our high standards of quality. Additionally, we have invested in an automatic drilling machine, loading and unloading connection line. This integration streamlines operations, reducing manual labor and minimizing errors. By automating these processes, we not only increase productivity but also free up resources to focus on quality control and innovation. Our commitment to equipment excellence ensures that our furniture production line operates at peak performance, resulting in faster turnaround times and superior products.

Continuous Innovation and Customer Satisfaction

At EKEN CNC, we believe that innovation is key to maintaining customer satisfaction. By continuously improving our technology and production processes, we ensure that our furniture production line remains at the forefront of the industry. We actively seek feedback from our clients to refine our offerings further, reinforcing our dedication to meeting their specific needs. The integration of electronic saw connect edge banding machine production lines exemplifies our commitment to innovation. This technology enhances the precision of cuts and joins, significantly improving the overall quality of the finished product. Our team is dedicated to providing solutions that not only meet but exceed customer expectations, ensuring that each project is a success.

Conclusion

In conclusion,EKEN CNC is poised to set the way in the furniture manufacturing sector with our advanced EKEN Thailand Panel Furniture Production Line. Our focus on following up on customer needs and factory area customization allows us to meet diversified customization demands effectively. With our reliable machinery, including double-end edge banding machines and automatic drilling systems, we are committed to enhancing efficiency and quality in our furniture production line.

Introducing EKEN CNC: Reliable Panel Furniture Production

At EKEN CNC, we take pride in our commitment to excellence in the furniture industry. Our focus is on providing trusted solutions that cater to the evolving needs of our customers. With our innovative EKEN Thailand Panel Furniture Production Line, we are set to transform the way furniture is manufactured, making it more efficient and tailored to individual preferences.

Meeting Diverse Customization Needs

In today’s fast-paced market, it’s essential to follow up on customer needs and factory area customization to meet diversified customization requirements. We understand that every client has unique specifications, and our furniture production line is designed to accommodate these variations. By utilizing advanced technology, we ensure that our production lines can adapt to different styles and designs, allowing for a seamless integration of customization in every project. Our approach is not just about meeting the current demands but also anticipating future trends. This proactive strategy helps us stay ahead in the competitive landscape, ensuring that our clients receive the most innovative solutions available in the market.

Advanced Machinery for Enhanced Efficiency

Our EKEN Thailand Panel Furniture Production Line features reliable machinery that enhances production efficiency. One of the standout components is the double-end edge banding machine production line. This technology allows for precise edge finishing, ensuring that every piece of furniture meets our high standards of quality. Additionally, we have invested in an automatic drilling machine, loading and unloading connection line. This integration streamlines operations, reducing manual labor and minimizing errors. By automating these processes, we not only increase productivity but also free up resources to focus on quality control and innovation. Our commitment to equipment excellence ensures that our furniture production line operates at peak performance, resulting in faster turnaround times and superior products.

Continuous Innovation and Customer Satisfaction

At EKEN CNC, we believe that innovation is key to maintaining customer satisfaction. By continuously improving our technology and production processes, we ensure that our furniture production line remains at the forefront of the industry. We actively seek feedback from our clients to refine our offerings further, reinforcing our dedication to meeting their specific needs. The integration of electronic saw connect edge banding machine production lines exemplifies our commitment to innovation. This technology enhances the precision of cuts and joins, significantly improving the overall quality of the finished product. Our team is dedicated to providing solutions that not only meet but exceed customer expectations, ensuring that each project is a success.

Conclusion

In conclusion,EKEN CNC is poised to set the way in the furniture manufacturing sector with our advanced EKEN Thailand Panel Furniture Production Line. Our focus on following up on customer needs and factory area customization allows us to meet diversified customization demands effectively. With our reliable machinery, including double-end edge banding machines and automatic drilling systems, we are committed to enhancing efficiency and quality in our furniture production line.

Wonderful! Share this Blog:

Categories

Ekenmac Secures Major European Order: Russian Customer Once Again Chooses Eken’s Composite Door Production Line

The Future of Door Manufacturing is Here: Automated & Smart

One Belt and One Road Woodworking Machinery Solutions

Eken Woodworking Machinery Ships Custom Solution to Jordan

Last-Minute Christmas Rush: Secure Your Woodworking Machinery Now!

Eken Woodworking Machinery: Speed and Trust in Action for Bangladesh Customer