Feature

1.Solid wood composite door, PVC paint-free door, ecological door, and large board pressing

2.Pressing temperature: ranges from 40°C to 80°C

3.Pressing open size: about 80 mm (for one door)

4.Pressing capability: about 120 seconds for each wooden door and 120 seconds for each wooden plate (depending on the material)

5.Closing time: about 6 seconds

6.Material entry and exit time: 12 seconds for each door (The duration is adjustable and can be set to synchronous material entry and exit.)

7.Glue used: white latex (solid content: 45%), PUR, A/B glue, and fireproof glue

8.Water content: The water content of wood and filling materials must be less than 13%. (lf the water content is too high, the pressing time will be affected.)

9.Flatness: fixed thickness sanding (the flatness affects the pressing effect). The difference between the framework and the filler must be within ± 0.2mm.

10.Yield: 30 doors per hour, 240 doors per eight hours; and 30 plates per hour

11.Connection: The product can be directly connected to a quadrilateral saw for cutting the edge.

Technical Specifications

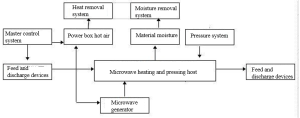

1.System components:

Door panel conveying system, microwave heating cavity, hydraulic pressure system, control and detection system, and dehumidification and heat dissipation system

2. Main parameters:

1) Microwave frequency: 2450±5 MHz

2) Microwave power: 0 – 60 kW (adjustable)

3) Pressure station motor power: 4 kW (Siemens)

4) Drive motor power: 2.2 kW (XW-59-1.5)

5) Rated pressure: 0-50T (four oil cylinders)

6) Dimensions of the platen table (length x width): 2440 mm x 1220 mm

7) Pressing cavity with microwave heating: stainless steel heated on all sides

8) Dimensions (H x W x D) of the microwave fast press: 3600 mm x 2400 mm x 2500 mm

9) Press open size: about 80 mm

10) Mainframe structure: The gantry and upper and lower platens are welded with national standard carbon steel plates.

Cooling mode of the microwave system: forced air cooling of the microwave source, and self-cooling industrial microwave variable frequency power supply

11) Control system: Siemens PLC programmable controller hand automatic control

12) Low-voltage electrical appliances: Siemens electrical appliances

Magnetron: Panasonic

13) Timing control: 0-999 minutes and 99 seconds (PLC self-control)

14) Control Ul: Siemens true-color touchscreen

15) Microwave leakage: complies with the inspection standard of the National Woodworking Machinery Quality Supervision and Inspection Center.

16) Electrical safety: complies with the GB5226 electrical safety standard.

17) Gun nails can be used for pre-installation. The nail size cannot be greater than 2 mm. Two gun nails are not allowed in the same position.

18) The PP board is used as the mother board.

Application

FAQ